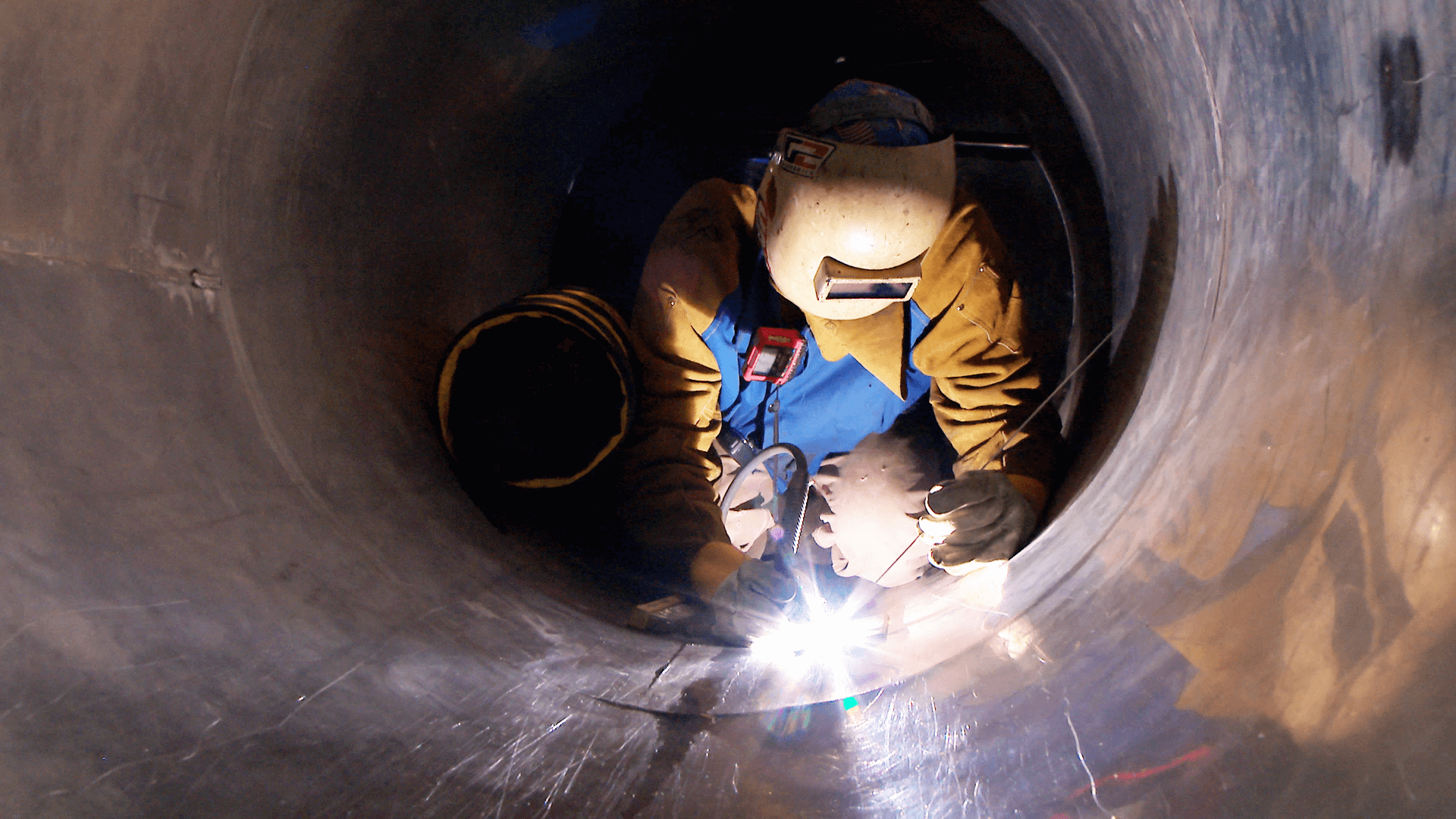

The two-lettered term ‘confined space’ may turn into the life-taker of the people. Displacement of oxygen gas can summon brain death within a few minutes. Therefore, workers who work in a confined space must sketch a plan per OSHA confined spaces standards.

5 Essential Steps To Boost The Safety Level In Confined Space

Before moving into a confined space, checking the safety level is highly important. Here are five tips that will be beneficial to increasing the safety level.

- Proper Plan: First, one should be aware of the confined space of their region earlier. With the appropriate knowledge, they can prepare themselves. In the first step, they must sketch a proper plan for the suitable kit. One must figure out which equipment can regulate climate threats and prevent sudden calamities. The goal helps convey how much preparation is required for that space. And all the workers must follow the plans. It’s proclaimed that untrained workers are responsible for mishaps.

- Detect Risks: Gas dominance inside the confined space is the primary reason for risk. Before entering the area, one should detect which gas can create danger. The worker should design the actions to stave off the impending threat. It’s necessary to remember that the risk is different in all confined spaces. Each space carries various types of hazards. The worker must train themselves as per the types of dangers.

- Essential Equipment: When the worker becomes familiar with the dangerous gas of the confined space, they should collect the tools as per the situation. A high-grade gas detector with a sensor is a must. After choosing the suitable sensor, the monitor will also be picked up. In this case, a bump test is first. The bump test works like a gas detector of the sensor. It sends an alarm after detecting harmful gas in space. The second step is calibration. It can alert the workers about the reading capacity of gas concentration. The third is zeroing. It can help the worker by formulating baselines. As per OSHA confined spaces standards, these three steps are vital.

- Sampling Pump: Driving air from the narrow space to the gas detector can decrease the threat level. Therefore, the workers always have to carry a slumping pump with them. There is a standard process for identifying the gas threat. The workers plunged the detector into the space by hanging it on a string. It can only sometimes determine the gas hazard. Instead, the workers can operate a sampling pump.

- Continuous Observation: Checking out the possibilities of gas risk once at the beginning is not sufficient. To keep safe in a confined space, the workers should repeatedly observe the level of trouble. If the risk is detected once at the entering period, the workers should stay alert till the end of their task.

Conclusion

Though the spoken-off tips will be practical enough for the workers in the confined space, the other workers must be attentive too. If they get any signal of threat, instantly, they should go forward to help them. Workers who frequently work in confined spaces should always be more conscious of their actions and equipment. They must train themselves in OSHA confined space standards.